What in tarnation!?

In today’s webinar, Semi-automatic hex meshing of complex parts with Coreform Cubit (YouTube link), I picked two excellent and moderately challenging examples to show how Cubit shines in creating beautiful hex meshes even on complex geometry. At Coreform we prefer to provide you with live webinars, rather than pre-recorded webinars, to better support interaction with our attendees and to provide you with an unfiltered experience. As always, I practiced the meshing process several times and made journal files that I could refer to during the webinar. The two variables I didn’t control was that I used a release candidate of our upcoming Coreform Cubit release instead of the latest production release and that I spontaneously improvised to show some interesting Cubit features. Then right when my beautiful mesh was about to pop out…Coreform Cubit crashed! And my other demo didn’t go as well as I’d hoped either. Dang!

In any case, sometimes it’s easiest to learn when things go wrong, and it’s always best to learn from someone else’s mistakes so, rather than delete the webinar, we went ahead and uploaded it so that you can learn from mine! Everything you will learn there is still helpful and useful. If you want to know where things went wrong, read on. You can download the geometry and successful journal files I used in the webinar here:

- Door lock assembly:

- Journal file: mesh_door_lock.jou (2.7 KB)

- CAD: Door_Lock_Assembly.sat (828.7 KB)

- NIST Gearbox housing

- Journal file: mesh_NIST.jou (4.9 KB)

- CAD: nist_ctc_02_asme1_rc.stp (1.1 MB)

Door Lock Assembly

The mistake I made meshing the door lock assembly was that I only did the first two commands in the

### Composite linking surfaces that have unsweepable topology section of the mesh_door_lock.jou file and skipped the other two.

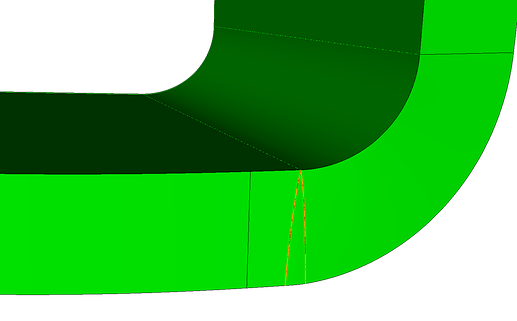

One of the two pairs of bad linking curves that I forgot about!

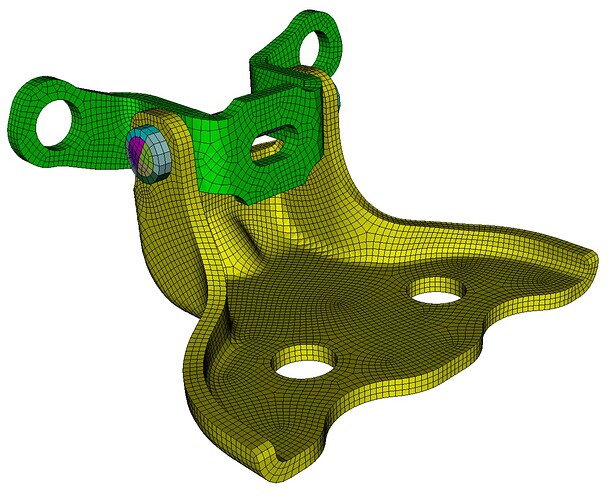

What we would have seen if I hadn’t skipped a step!

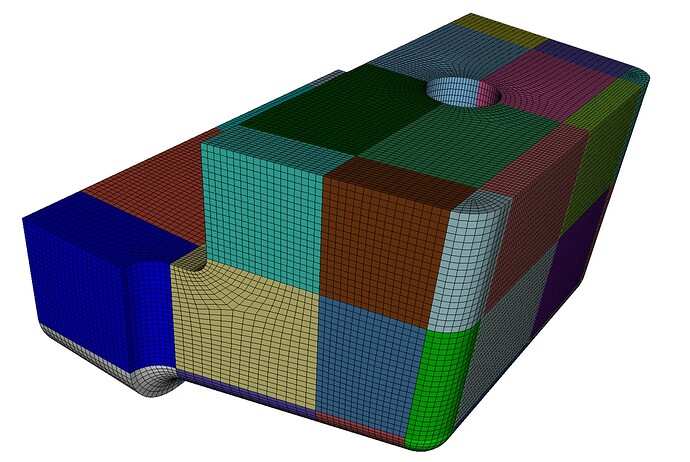

NIST Gearbox Housing Detail

The mistake I made in the meshing the detailed region of the NIST Gearbox Housing is that I typically wait to do compositing until the final step before meshing (I consider imprint and merge to be part of meshing) as demonstrated in my journal file.

But during the webinar I wanted to show why I was making certain webcuts and how we’d clean them up with compositing… so then I was webcutting on composited volumes which meant my geometry IDs were suddenly different, and then I made (at least) one wrong webcut because of these different IDs. (I had my journal file open on my other screen / was referring to it as I went)

The beautiful mesh that you were deprived of witnessing

In any case, Cubit shouldn’t have crashed - even if I was using a pre-release version today. We treat hard-crashes as critical bugs so I’ve already added the bug into our issue tracker. I have been using Cubit for nearly a decade but, while it’s generally very robust, it’s far from perfect. Anyways, I thought it would be helpful to share what I learned with you so that you can learn from it!

Happy meshing!