Hello,

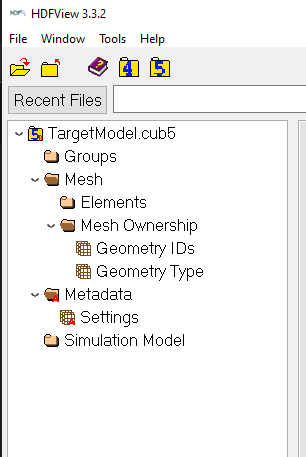

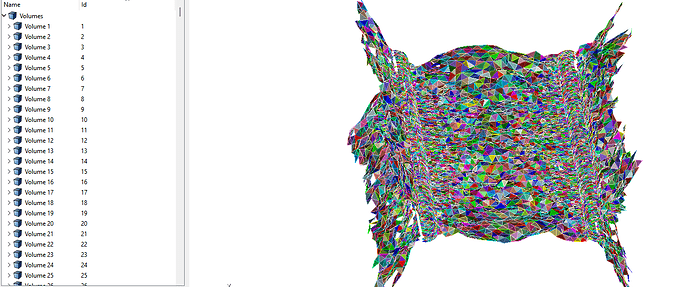

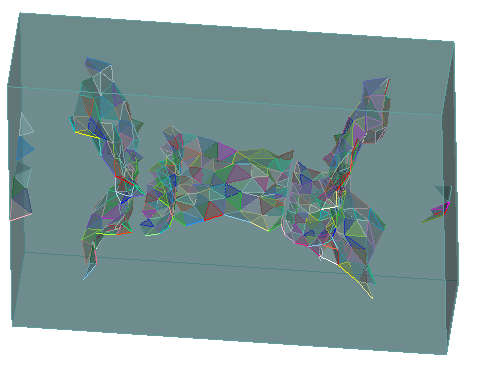

I am working with Cubit and trying to automate a process involving volume subtraction, but I am encountering several issues related to problematic geometry. I would like assistance from an expert to understand how to resolve these issues efficiently, as doing it manually for each volume is not practical given the large number of volumes I am working with.

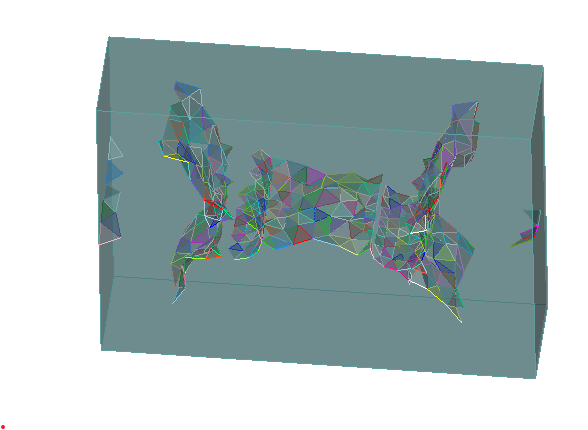

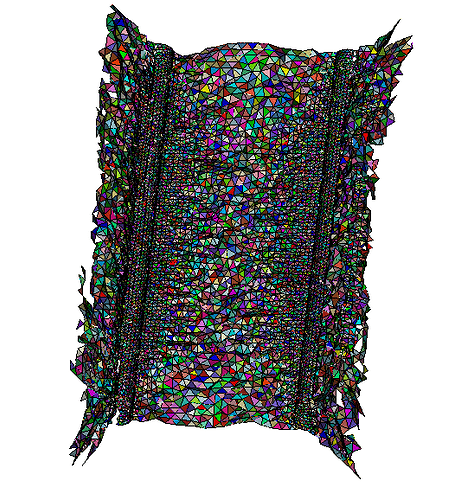

Objective: I have a set of solid volume elements representing a damaged state in my simulation. I created a new volume, and I want to subtract all the other existing volumes from this new volume. The outer shape of the subtracted volumes is essential as it represents a damage pattern crucial for my analysis. However, these volumes are problematic; they may:

- Penetrate each other

- Have small gaps between them

- Be very thin or flat

While their geometry is imperfect, their overall arrangement is necessary to represent the damaged state accurately.

Steps I Followed:

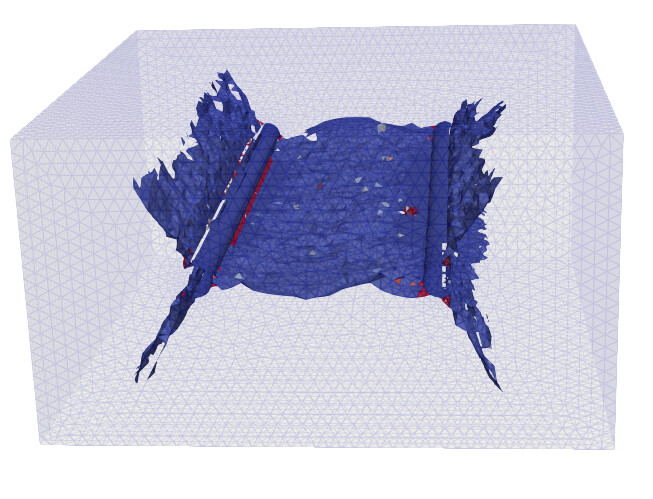

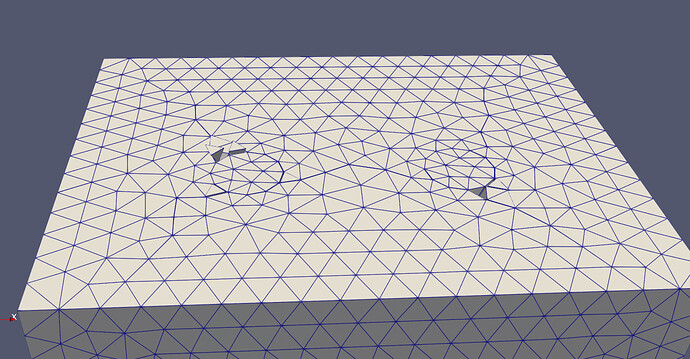

- Created a New Volume:

- This is the volume from which I want to subtract all the other smaller volumes.

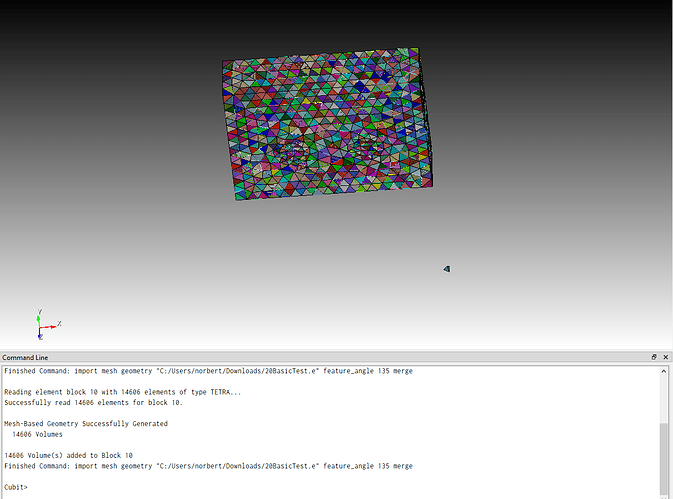

I’v attached the small example and the real volumes I need

- Subtraction Attempt:

- Command: subtract volume [range of volumes] from volume [main volume]

- This operation fails with several errors like:

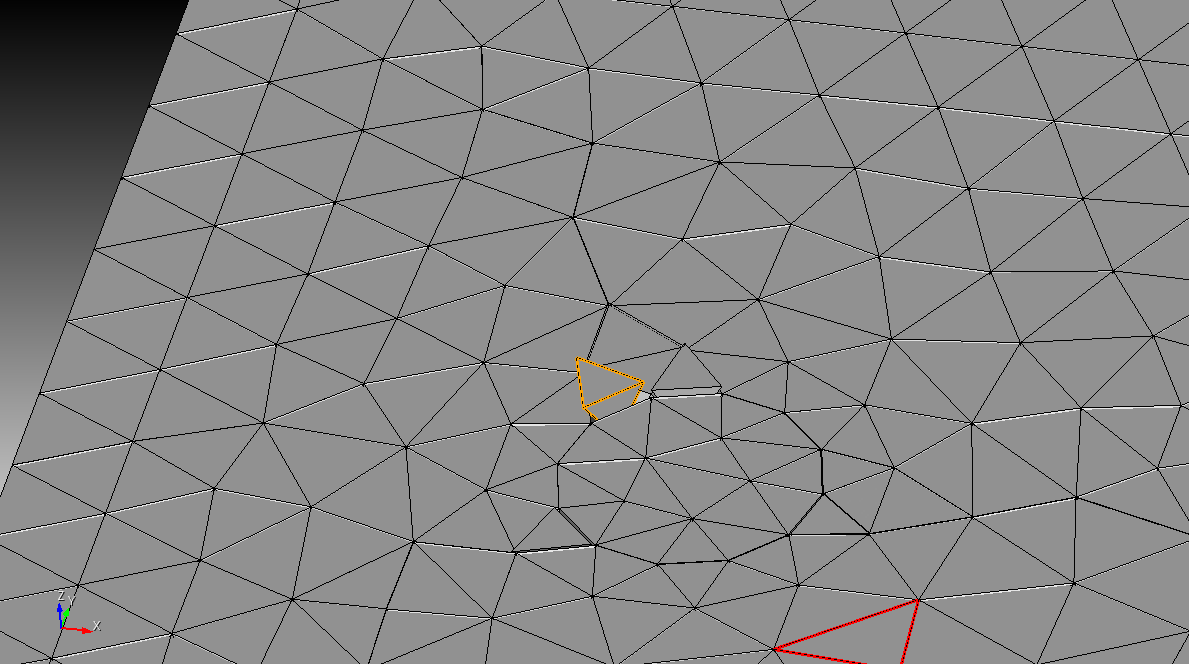

- Coincident face intersections

- Non-manifold edges

- Inconsistent face-body relationships

- Validation and Geometry Checks:

- Validate volume all – Revealed multiple issues (zero volume, bad surfaces, duplicate vertices, bad edges, etc.)

- Quality volume all – Highlighted thin regions and problematic areas.

- Intersect volume all – Showed that some volumes intersect with each other.

- Manual Fixes:

- Reversing surfaces for orientation issues.

- Deleting and recreating volumes from surfaces.

- Addressing individual volume issues (works but is not feasible due to the large number of volumes).

- Tolerance Adjustments:

- Healer Default StitchMinTol 0.001

- Healer Default StitchMaxTol 0.05

- Healer Autoheal Volume all

- tolerance boolean 0.001

- This did not resolve the subtraction issues.

- Additional Checks and Attempts:

- List edge all and list edge with problems.

- Thicken sheet body all by 0.001 (did not work as they are solids)

- Boolean unite volume all (failed with similar geometry issues)

- Partial Success:

- When I manually fix specific problematic volumes and subtract them individually, it works.

- When I attempt to subtract the entire range of volumes at once, I get error messages, but a new volume is still created. Was the subtraction fully successful?

Current Roadblock:

- Manually fixing each volume is time-consuming and impractical for my large dataset.

- Automated healing and tolerance adjustments did not solve the subtraction issues.

- I need an efficient and automated workflow to handle these problematic volumes and perform the subtraction.

Request:

- Are there any specific best practices or tools in Cubit to automatically resolve volume issues before Boolean operations?

- Can the subtraction process be made more robust for imperfect geometries?

- Is there a more efficient workflow to handle intersecting or nearly coincident volumes without manually fixing each one?

- How can geometry be simplified? Is it possible to remesh a meshed volume? I converted the meshing to volumes because I didn’t find a way to remesh.

I would appreciate any advice or guidance on how to proceed. If needed, I am open to discussing this further in a Zoom meeting.

Thank you for your support!

Best,

Gili Lifshitz Sherzer