I really appreciate the help from Coreform company 4 months ago. Now I have successfully completed my undergraduate graduation thesis and won the honor of excellent graduation thesis of Tsinghua University. Now I am very glad to share my achievements on this forum.

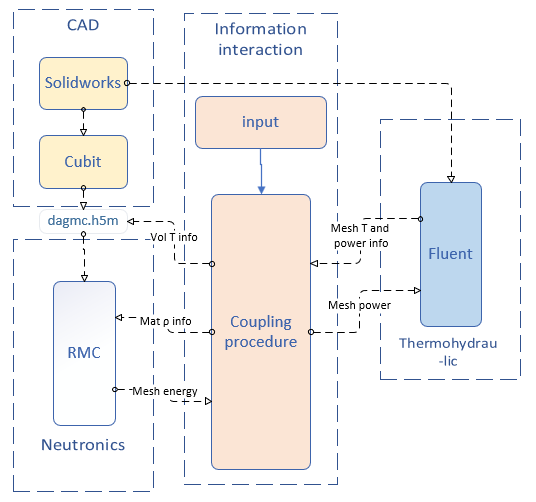

The work of this paper is to establish a neutronic-thermal coupling framework based on special geometry. Neutron physics calculation uses monte Carlo software RMC based on CAD geometry, which requires Cubit to provide HDF5 files.The commercial CFD software Fluent is used for thermal-hydraulic calculation .A neutronic-thermal coupling method based on the special geometry is established. The coupling frame diagram is shown below:

Neutronic-thermal coupling based on special geometry.pdf (8.6 MB)

I’m sorry that the thesis was written in Chinese, and an English abstract is given here:

Fuel assembly is one of the most important components of nuclear reactor. The development of high-performance fuel assembly to improve the power density, safety margin and economy of the reactor core is an important direction of nuclear energy development.Now cylindrical rod fuel is widely used in nuclear power plants because of its simple structure and convenient processing, but its performance is general.Although special-shaped geometry has better thermal-hydraulic performance, the reason why it is difficult to popularize is its processing and manufacture.However, the development of additive manufacturing technology has developed the design and manufacturing potential of special-shaped geometry fuel elements, and the research on special-shaped geometry is increasingly important.At present, there are few neutron physics calculations in special-shaped geometry and the neutronic-thermal coupling coupling is basically blank. Therefore, this paper takes the helical cruciform fuel(HCF) rod as the research object, explores its strengthening heat transfer mechanism, analyzes the characteristics of nuclear heat coupling, and establishes a neutronic-thermal coupling framework based on special-shaped geometry.

Firstly, the neutronic and thermal-hydraulic performance of HCF rods are numerically simulated by using the CAD-based Reactor Monte Carlo code RMC and the commercial computational fluid mechanics software Fluent respectively, and compare it with the traditional cylindrical and non-twist cruciform fuel rods. The results show that the helical cruciform structure slightly reduces the reactivity and increases the radial power peaking factor. Compared with cylindrical fuel rods, the HCF rods can enhance coolant mixing and heat transfer due to their transverse flow characteristics. In the 7-rods assembly calculation, the mean and peak temperature of HCF rods are reduced by 4K.

Second, because of the neutron physics and the thermal-hydraulic in reactor are tightly coupled, in order to further close to the real physical process, a coupling program is developed to realize the data interaction between RMC and Fluent, and a neutronic-thermal coupling framework suitable for special-shaped geometry is established and applied it to the calculation of 7-rods assembly calculation.

The results show that the neutronic-thermal coupling coupling can reflect the negative feedback effect of the reactor, and keff decreases after the coupling calculation. Meanwhile, The axial power peak factor and uneven temperature distribution increased, and the peak fuel temperature increased by about 40K, only when the neutronic-thermal coupling is considered can the reactor design be conservative.

Finally, in view of the geometric design freedom provided by additive manufacturing and and combined with the design idea of HCF, this paper proposes a integrated rector core structure with helical cruciform coolant channels. The analysis results of neutron physics and thermal-hydraulic show that the power distribution is flat and the power peak factor is small.Although the helical cruciform coolant channels increases the pressure drop and decreases the flow characteristics, its heat transfer area increases by 30%, it decreases by 14K relative to the circular inner passage when the total heat release of the core is equal.